Please... for the love of all that is good and evil, help me understand how to program a simple analog program! I have a 10 ohm potentiometer wired in correctly (I believe) between the plus side of the circuit, and the negative is coming straight from a 5v DC power supply. I have my SLC 500 1747 NI-4 set to volts as opposed to current.(how come I can't quite understand the difference between current and voltage??? granted two weeks ago I had no idea what any of this stuff was.)

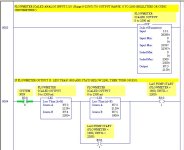

Second, I have a SCP function in RSLogix 500 that works respectively to the turning of the potentiometer, and it does indeed perform correctly. So basically I understand most of analog and the concept, but my next question is, what can I do in the program next to make those variable numbers trigger something and how do I do it. I have spent many hours looking for help, how-to, and tutorials but I am still scratching my head. Does it involve the move function maybe?? Any help PLEASE!

I have RSLogix 500, a SLC 5/03, 1746 NI4, and one of each ac,dc, inputs and outputs, and one ow16 relay output card.

Could someone please just give me an example of how you could use the variables to trigger different outputs? I think that would really clear things up, especially to see an actual program.

Thanks in advance,

Joe.

Second, I have a SCP function in RSLogix 500 that works respectively to the turning of the potentiometer, and it does indeed perform correctly. So basically I understand most of analog and the concept, but my next question is, what can I do in the program next to make those variable numbers trigger something and how do I do it. I have spent many hours looking for help, how-to, and tutorials but I am still scratching my head. Does it involve the move function maybe?? Any help PLEASE!

I have RSLogix 500, a SLC 5/03, 1746 NI4, and one of each ac,dc, inputs and outputs, and one ow16 relay output card.

Could someone please just give me an example of how you could use the variables to trigger different outputs? I think that would really clear things up, especially to see an actual program.

Thanks in advance,

Joe.