The mechanical design is going to be the most critical thing for accuracy and repeat-ability.

To prove the mechanical design, you should be able to use a test weight with the conveyor not running and get the same summed value when you place the weight at various points across its length and width. You may not be able to get accurate results at every point, but you need an area in the center from which you can take a number of samples for averaging.

Next, you may consider how to set up this area for sampling when the conveyor is running. I replaced the control system on an in motion check-weigher for cartons but had the benefit of starting with a proven mechanical design.

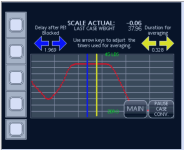

Since I am weighing a variety of case sizes and weights, I used a graph on the HMI to show the summed weight value as boxes travel across it. I record these samples every 10ms in the PLC using an array of real numbers and used a scatter graph in the Red Lion G306 to display them. On that graph, I superimposed two vertical lines which represent the area to begin and end the samples used for the final case weight calculation.

This way, the technician can adjust the rather narrow band used for the final weight calculation by moving those vertical lines with the graph as a visual aid.

I only used one photocell at the leading edge to begin the recording of samples, and those vertical lines from the HMI end up as timer presets to set when to start and end the averaging for the final weight value.

I used a Compactlogix PLC with a Hardy Instruments scale (HI-1769-WS) module to do a lot of the grunt work for me at high speeds. I also used their IT summing board for its ability to perform corner balancing by allowing each of the four load cells to be isloated. My scale has adjustment screws at each load cell so you can get them all to register their "fair share" of the weight.

I think I posted a screen shot somewhere of my graph screen which may help you understand what I am trying to describe. I will hunt for it.