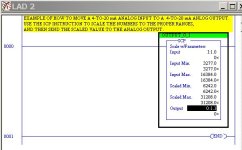

Okay, I don't know why I can't figure this out. I have a 2 axis joystick wired into my analog IO card on my SLC5/03 rack (os302 i think). I have scaled my parameters and have made little sample programs with outputs turning on at set limits and what not, but how the heck do I wire and program the analog output side of things?! I have motors, leds, batteries, resistors, whatever! I just need someone to show me how you vary an analog output, with regards to what the analog input is reading. I have searched and searched but I just need a sample program to learn by.

Thanks everyone.

Joe.

Thanks everyone.

Joe.