Hi guys

I did a few PLC courses in electrical college but the 2nd was quite poorly run.

Getting back into the work of programming PLC's as was just wondering if anyone here knew of any resources for practise assignments?

Just some cool projects I could work on and gain experience.

one more question....

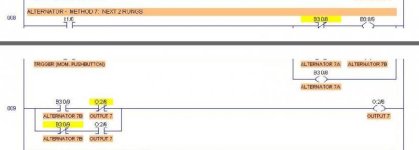

At college one of the problem questions we had was to make a single push button turn a relay on and off.

no timers, OSR etc...just straight ladder logic

One of the guys if I recall correctly did it in about 3 lines of logic....

I did search the forums but didn't find an exact solution..I saw alot of people getting called out for not searching first, so sorry but the answers didn't apply to this problem

(at least the ones I found)

I did a few PLC courses in electrical college but the 2nd was quite poorly run.

Getting back into the work of programming PLC's as was just wondering if anyone here knew of any resources for practise assignments?

Just some cool projects I could work on and gain experience.

one more question....

At college one of the problem questions we had was to make a single push button turn a relay on and off.

no timers, OSR etc...just straight ladder logic

One of the guys if I recall correctly did it in about 3 lines of logic....

I did search the forums but didn't find an exact solution..I saw alot of people getting called out for not searching first, so sorry but the answers didn't apply to this problem

(at least the ones I found)