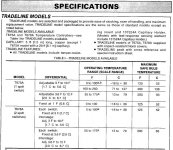

Hi, can anyone help me in understanding how this controller functions. I'm trying to mimic the control of this temperature controller with ladder logic using RsLogix 500 CPU Slc 5/04, 1746-ow16, 1762-nr4. I'm using this switch for heating application

Here’s how I understand this:

If the temperature set-point on the dial is set to 45 deg. Fahrenheit and the temperature begins to fall below the set point then MAKE R-W on right switch.

I’m not quite sure about the Interstage Differential and how it functions, but here is how I think of it. So if the SP= 45Deg F and the Interstage differential =10 Deg F then the R-W contacts would break at 55 Deg F. And again make at 45 Deg.

I don’t understand what sets the left switch differential?

Any help greatly appreciated.

Here’s how I understand this:

If the temperature set-point on the dial is set to 45 deg. Fahrenheit and the temperature begins to fall below the set point then MAKE R-W on right switch.

I’m not quite sure about the Interstage Differential and how it functions, but here is how I think of it. So if the SP= 45Deg F and the Interstage differential =10 Deg F then the R-W contacts would break at 55 Deg F. And again make at 45 Deg.

I don’t understand what sets the left switch differential?

Any help greatly appreciated.

Last edited: