kallileo

Lifetime Supporting Member

I have a level sensor with resolution 5mm which is connected 10 bit analogue input of the PLC.

The level sensor is installed on horizontal tank of cylindrical shape.

I have big problem with the accuracy of the reading of the sensor.

For example on 3000l tank when the float is located close to the middle of the tank (1500l) this accuracy error is the biggest.

At 1500l even if the water in the tank is not moving at all I get on the screen a measurement that could be in the range of 1470l to 1530l. The current value of the reading changes every second between the aforementioned range.

If I have 200l in the tank the range is no more 4-5l.

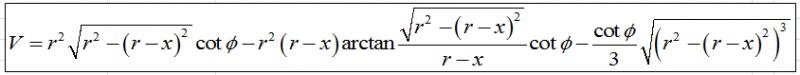

All this looks reasonable to me because in the middle of the tank the displacement of 5mm on the rod is around 20l and on the bottom 5mm it could be as low as 5l.

Is my only solution to replace the level sensor with some other type with better resolution?

Is there any other way (in the program of the PLC) to decrease this error range in the middle of the tank?

You can see the sensor below:

http://www.deeter.co.uk/products/fl...s-series-stainless-steel-liquid-level-sensors

The level sensor is installed on horizontal tank of cylindrical shape.

I have big problem with the accuracy of the reading of the sensor.

For example on 3000l tank when the float is located close to the middle of the tank (1500l) this accuracy error is the biggest.

At 1500l even if the water in the tank is not moving at all I get on the screen a measurement that could be in the range of 1470l to 1530l. The current value of the reading changes every second between the aforementioned range.

If I have 200l in the tank the range is no more 4-5l.

All this looks reasonable to me because in the middle of the tank the displacement of 5mm on the rod is around 20l and on the bottom 5mm it could be as low as 5l.

Is my only solution to replace the level sensor with some other type with better resolution?

Is there any other way (in the program of the PLC) to decrease this error range in the middle of the tank?

You can see the sensor below:

http://www.deeter.co.uk/products/fl...s-series-stainless-steel-liquid-level-sensors