Hello everyone,

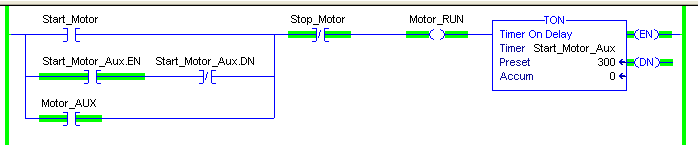

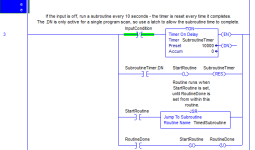

After starting a motor pump, I have to wait 300 ms before to check a feedback signal from the motor pump. How I can make a small function (subroutine) delay in Ladder on the same rung to wait this time immediately ?

I'm using RSLOgix 5000 for the first time with 1769-L32E CompactLogix controller.

After starting a motor pump, I have to wait 300 ms before to check a feedback signal from the motor pump. How I can make a small function (subroutine) delay in Ladder on the same rung to wait this time immediately ?

I'm using RSLOgix 5000 for the first time with 1769-L32E CompactLogix controller.