Medicine Dispenser

We are doing a plc-based project, medicine dispenser, we are told to dispense medicine at user's desired time intervel and number of times per day. When it is time to dispense, a buzzer will sound to alert the user. The buzzer sound will be deactivated when the user opens the dispenser drawer(with motion sensor attached), take the medicine and closes it. After 8 rounds of dispensing medicine, it will alert the user to refill the medicine dispensing compartment.We are using Matsushi ta FP0-C14CRS Terminal Block Type PLC with two expansions sets of FP0-E16RS for the inputs and outputs.

Help we need:

We are doing a plc-based project, medicine dispenser, we are told to dispense medicine at user's desired time intervel and number of times per day. When it is time to dispense, a buzzer will sound to alert the user. The buzzer sound will be deactivated when the user opens the dispenser drawer(with motion sensor attached), take the medicine and closes it. After 8 rounds of dispensing medicine, it will alert the user to refill the medicine dispensing compartment.We are using Matsushi ta FP0-C14CRS Terminal Block Type PLC with two expansions sets of FP0-E16RS for the inputs and outputs.

Help we need:

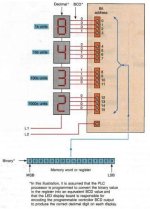

- For the customized time intervel, we would like to have a 1-9 up and down counter and for the customised number of times per day a 1-5 up and down counter. We need help to design a circuit diagram and also like to know how to connect the 7-segment display to the PLC.

- We also want the medicine dispenser to be idle from the last intake of the day to the following morning (approximation of 7hrs).

- We would like to have a circuit of how to link the buzzer and motion sensor.