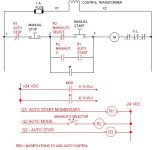

I don't understand why my first schematic will not work in PLC auto mode.

A review of your drawing is what you asked for, and below I am commenting on your drawing, not your logic, your intentions, or your PLC program.

Your drawing will not work in PLC Auto Mode because you have not shown any physical way to get the PLC Inputs for "PB2" and PB3" into your PLC. For example, look at the Auto-Manual Selector Switch SS1. In your FIRST schematic drawing in Post #1 at the top, you show SS1 with TWO contacts, one for manual, one for auto. You use the manual one in the physical wiring, and you use the auto contact in your lower scematic for the PLC wiring. That is as should be, except that the left side of the second SS1 contact must be wired either to the PB1 Emerg Stop button or directly to 120 volts. In the top scehmatic you show it wired to PB1, but in the bottom PLC schematic, you show the left side of PB1 wired to 120 volts. It cannot be both!

However, for PB2, you have already used the ONE contact in the manual START PB, so there is nothing left for the Auto PB2 that is wired directly to the 120 volt power in your PLC wiring. You cannot use the same PB2 contact in TWO places (that are wired differently). If PB2 has two separate contacts, then those must be shown as such and labeled as such.

The same goes for PB3: you used it as a STOP button, with one side (wire 21) going to SS1 and the other side (22) going to the Start button. Now look at your PLC wiring. Here you show the ONE PB3 contact wired to 120 volts and PLC Input I/1. That is physically impossible. Either PB2 and PB3 have TWO sets of electrically separate contacts (WHICH ARE NOT SHOWN IN YOUR DRAWING), or you must provide separate pushbuttons (which should have different device numbers).

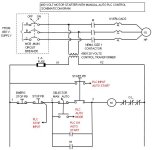

Notice that in the last drawing that I posted (Post #11), I show a place to put the STOP pushbutton PB3 so that only ONE contact is required for both the Manual and PLC Auto Input. For the Start button, I think the best method will require two contacts, and both those contacts should show on your drawing and be lableled (usually someting like "PB2-A" and "PB2-B").