Vedang Joshi

Member

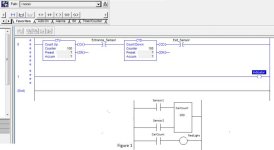

Hi guys I am completely new to plc programming and I have been trying to make a practice program for a lot that holds 100 cars. A counter must increment/decrement depending on if a car enters/exits. It should display the # cars at all times and show full if the limit is reached. So far I know the following:

I:1/0 = Entrance sensor (Count the number of vehicles entering the lot)

I:1/1 = Exit sensor (Count the number of vehicles leaving the lot)

O:2/0 = Indicate lot is full

I have began the code but I have no idea what to do next. Can anyone help?

Thanks

I:1/0 = Entrance sensor (Count the number of vehicles entering the lot)

I:1/1 = Exit sensor (Count the number of vehicles leaving the lot)

O:2/0 = Indicate lot is full

I have began the code but I have no idea what to do next. Can anyone help?

Thanks