anik

Member

Hi, I am a Graduate student and working with a Fluid Bed Dryer. My background is not in engineering, so I am facing a lot of troubles. I tried to learn by myself through different lecture videos without much success. Hope this forum would help me out.

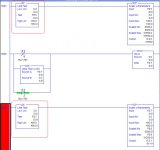

Our blower in the FBD stops working frequently. Earlier we used to do "Clear Fault" using RSlogix500 software in which the ladder logic program was written by a professional. The reason was said that "While resting, there is a pile up / overflow of negative/above max value for the blower, which causes the fault". Fault clear used to work, although, when I used to open that ladder logic program and go online, it used to show "RUN" not "FAULTED".

From last couple of months, the "Fault Clear" is not solving the issue. The blower stops working, I do the same thing (Clear Fault using RSlogix 500) but nothing happens. And surprisingly after couple of days the blowers starts by itself !!

From my experience of 4 months, the blowers stops working in a certain scenario. We use automation system using Delta V and Micrologix 1100. When the set value in the specific tag for blower flap position resides at maximum or negative value, and we start the power up for Fluid Bed without changing the value, the blower stops working and never comes back.

Can anyone help me out please. I am just getting frustrated without appropriate knowledge and skill in this arena.

Thanks,

Anik

Our blower in the FBD stops working frequently. Earlier we used to do "Clear Fault" using RSlogix500 software in which the ladder logic program was written by a professional. The reason was said that "While resting, there is a pile up / overflow of negative/above max value for the blower, which causes the fault". Fault clear used to work, although, when I used to open that ladder logic program and go online, it used to show "RUN" not "FAULTED".

From last couple of months, the "Fault Clear" is not solving the issue. The blower stops working, I do the same thing (Clear Fault using RSlogix 500) but nothing happens. And surprisingly after couple of days the blowers starts by itself !!

From my experience of 4 months, the blowers stops working in a certain scenario. We use automation system using Delta V and Micrologix 1100. When the set value in the specific tag for blower flap position resides at maximum or negative value, and we start the power up for Fluid Bed without changing the value, the blower stops working and never comes back.

Can anyone help me out please. I am just getting frustrated without appropriate knowledge and skill in this arena.

Thanks,

Anik