kapooski2012

Member

Hi there folks,

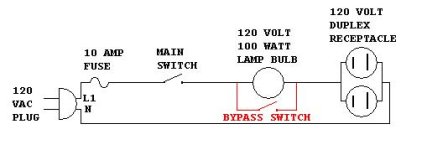

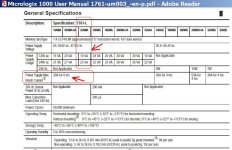

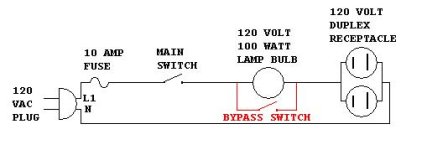

Just realized, after testing the small thermal 1.2 amp breaker I was planning to use on my PLC trainer is no good. I have several in-line fuse holder I can use. I guess I have a choice of slow blow, fast acting or ceramic and what would be the best....and if I start adding all the amperage of all the output plus the operating current of the PLC (which I could not find in the manual, unless I was looking in the wrong area) I imagine a fuse no bigger than 1.5 or even 2.0, but if were to go up to 3 or 4 would I melt or fuse something lol ? Plus I built the safety project that Ron Beaufort designed below adding my twist!

I dont how to add an image through the url, therfore I made it an attachement compliments to Ron Beafort, (hope I didn't break any copyright laws)

Just realized, after testing the small thermal 1.2 amp breaker I was planning to use on my PLC trainer is no good. I have several in-line fuse holder I can use. I guess I have a choice of slow blow, fast acting or ceramic and what would be the best....and if I start adding all the amperage of all the output plus the operating current of the PLC (which I could not find in the manual, unless I was looking in the wrong area) I imagine a fuse no bigger than 1.5 or even 2.0, but if were to go up to 3 or 4 would I melt or fuse something lol ? Plus I built the safety project that Ron Beaufort designed below adding my twist!

I dont how to add an image through the url, therfore I made it an attachement compliments to Ron Beafort, (hope I didn't break any copyright laws)