I've got a bit of a situation I could use some help with. I'm running RSView 32 on a Windows server which communicates with an ethernet I/P control network. The main interface for the application is in the server room which is not routinely manned, and the remote licenses in different parts of the plant are not manned constantly either. Occasionally RSView 32 is stopping, not necessarily crashing, and I need a way to remotely monitor the application to make sure it's still running. RSView generates some critical alarms and when it stops like that it's very possible to have MAJOR issues in the plant.

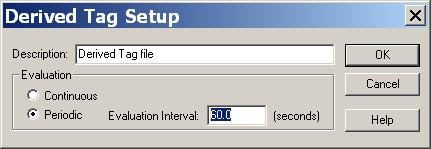

My first though was to use some sort of tag instruction to set a bit in another PLC on the network which would go false if the program were to stop. I've tried hidden n/c buttons, derived tags, event tasks, and I simply cannot get this thing to give me a simple bit that will go false if the program is not operating. If I periodically clear the target bit then if the application stops the bit will go false and not go back to true.

Have any of you guys tried to accomplish this? Am I totally on the wrong track?

Thanks

My first though was to use some sort of tag instruction to set a bit in another PLC on the network which would go false if the program were to stop. I've tried hidden n/c buttons, derived tags, event tasks, and I simply cannot get this thing to give me a simple bit that will go false if the program is not operating. If I periodically clear the target bit then if the application stops the bit will go false and not go back to true.

Have any of you guys tried to accomplish this? Am I totally on the wrong track?

Thanks