Where do I begin...

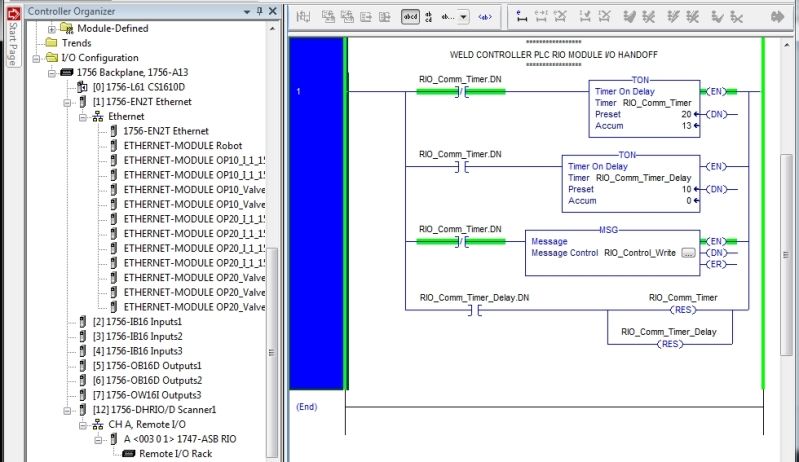

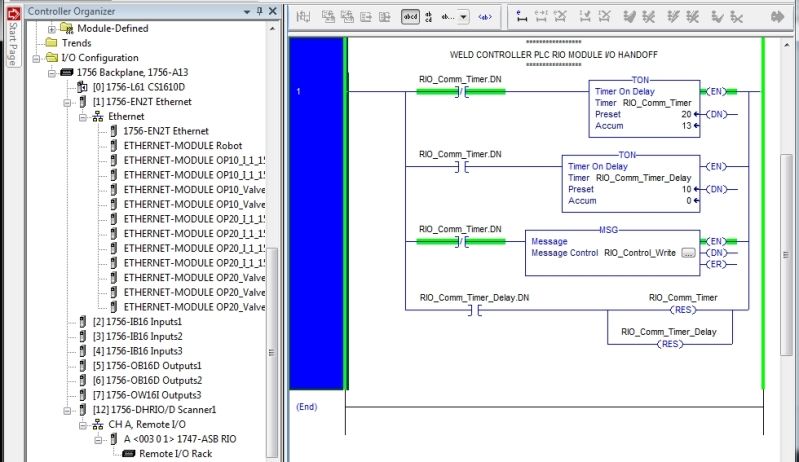

First I have a Compact Logix 5561, which has a 1756-DHRIO module attached, and that RIO module is wired to a MEDAR (RIO Module) that is connected to a SLC-5/03 PLC.

I have attached some pictures of the modules with this post.

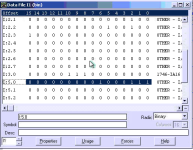

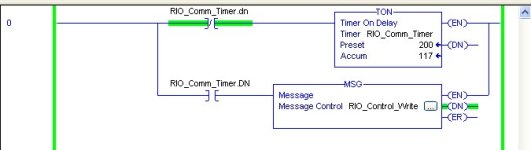

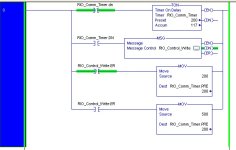

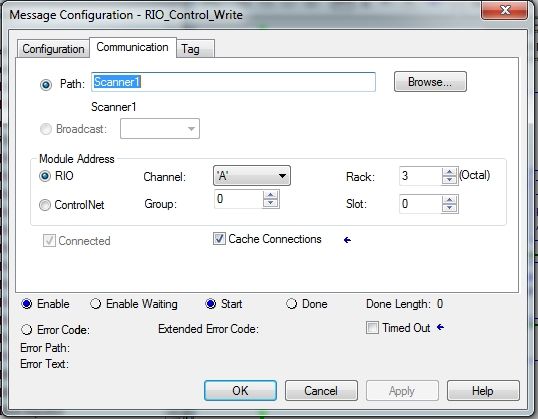

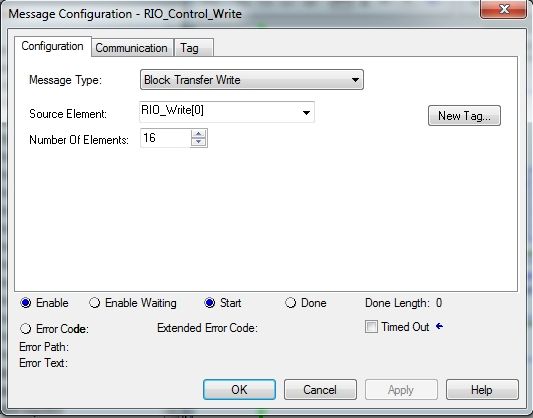

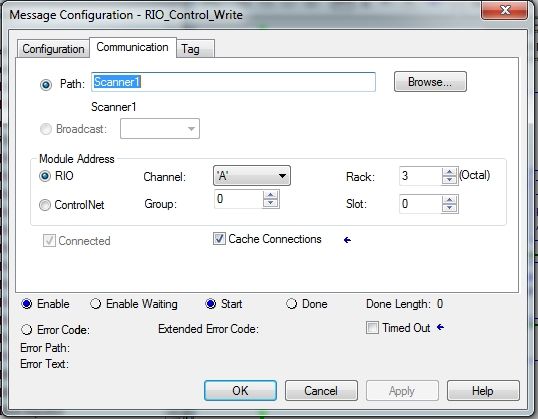

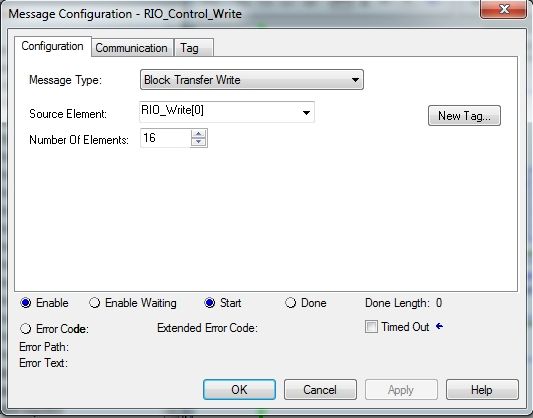

The 1756-DHRIO appears to be communicating just fine with the MEDAR RIO Module based on the communcition LEDs. However, when I try to setup a Message block (using Block Transfer Write) in RS5000, it is not sending the correct bits. It is instead sending the Element number (in binary) only for some odd reason. I have attached pictures to hopefully help you help me. Let me know if you need more information.

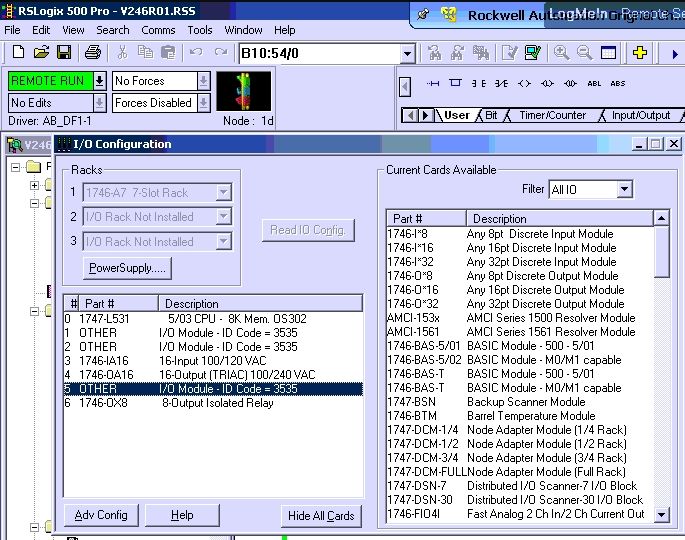

Here are some images of my RS5000 and RS500 configuration for the RIO modules:

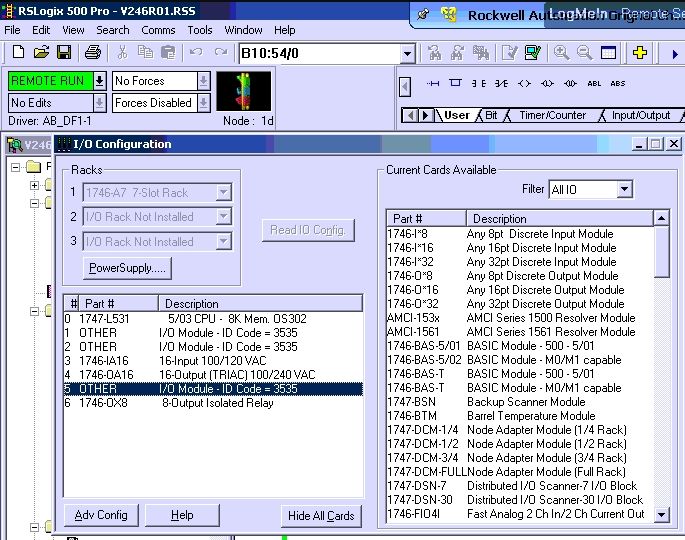

Note, in RS500, it does not allow me to modify the G file or M data since for some reason the MEDAR (RIO Module) comes up as Other, so I'm not sure if this is an issue or not.

First I have a Compact Logix 5561, which has a 1756-DHRIO module attached, and that RIO module is wired to a MEDAR (RIO Module) that is connected to a SLC-5/03 PLC.

I have attached some pictures of the modules with this post.

The 1756-DHRIO appears to be communicating just fine with the MEDAR RIO Module based on the communcition LEDs. However, when I try to setup a Message block (using Block Transfer Write) in RS5000, it is not sending the correct bits. It is instead sending the Element number (in binary) only for some odd reason. I have attached pictures to hopefully help you help me. Let me know if you need more information.

Here are some images of my RS5000 and RS500 configuration for the RIO modules:

Note, in RS500, it does not allow me to modify the G file or M data since for some reason the MEDAR (RIO Module) comes up as Other, so I'm not sure if this is an issue or not.