To All,

Please help,

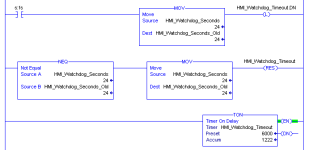

I am new to Rockwell automation and normally use Siemens, I am trying to finish up a program and now need to use a "Heart Beat" signal to throw an alarm if the panelview drops communication.

What logic do i need to write to make this happen?

I have looked and have found nothing to guide me and this code is different than Siemens.

I am using ladder logic to write my code.

Thank you all

Please help,

I am new to Rockwell automation and normally use Siemens, I am trying to finish up a program and now need to use a "Heart Beat" signal to throw an alarm if the panelview drops communication.

What logic do i need to write to make this happen?

I have looked and have found nothing to guide me and this code is different than Siemens.

I am using ladder logic to write my code.

Thank you all