mayank_04081989

Member

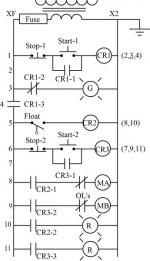

I'm given a ladder diagram as follows:

.

.

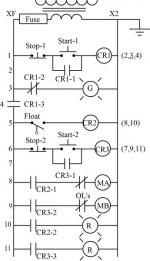

I need to have a PLC 5/30 control System. There are 8-point I/O cards with one-slot addressing. the input cards use slot 0 and the output cards use slot 1. I have constructed a PLC ladder diagram as follows:

The CR's in the problem are used as both input and output in the solution. Is it correct to address the outputs as inputs in PLC (as in the last four rungs)?

Greatly appreciate your help..

.

. I need to have a PLC 5/30 control System. There are 8-point I/O cards with one-slot addressing. the input cards use slot 0 and the output cards use slot 1. I have constructed a PLC ladder diagram as follows:

The CR's in the problem are used as both input and output in the solution. Is it correct to address the outputs as inputs in PLC (as in the last four rungs)?

Greatly appreciate your help..