Hello friends;

Good day.I have a presure transmitter of 0 to 100 inches of water column and give me 4 to 20 mA.

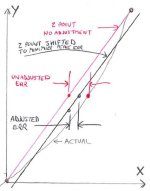

Today i calibrate it. I check at zero pressure it gives me 4.1 mA and at 100 it gives me 20.5 mA.

So i apply a pressure o , 25 , 50, 75 and 100 inches of water column. and set the 4 to 20 mA at zero and full range.

before calibrate i note the following value

at 25"w.c It gives me 25.3

at 50" w.c it gives me 50.2

at 75" w.c it gives me 75.2

and at 100 it gives me 100.3

How can i calculate the %age error of that transmitter?

Regards

Good day.I have a presure transmitter of 0 to 100 inches of water column and give me 4 to 20 mA.

Today i calibrate it. I check at zero pressure it gives me 4.1 mA and at 100 it gives me 20.5 mA.

So i apply a pressure o , 25 , 50, 75 and 100 inches of water column. and set the 4 to 20 mA at zero and full range.

before calibrate i note the following value

at 25"w.c It gives me 25.3

at 50" w.c it gives me 50.2

at 75" w.c it gives me 75.2

and at 100 it gives me 100.3

How can i calculate the %age error of that transmitter?

Regards