glplc_007

Member

Hello all, I'm looking for a push in the right direction with this one.

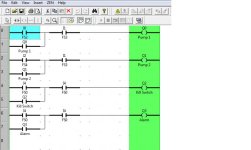

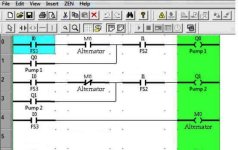

I'm in need to alternate two pumps using an Omron 10C3AR-A-V2 Zen program.

Here is the setup--

Float switch 2 - on - no operation

Float switch 3 - on - pump starts

Float switch 3 - off - continue pumping

Float switch 2 - off - stop pump

Which I have working great, but I cannot ,for the life of me, figure out how to get the other pump to run on the next cycle.

Any help is greatly appreciated.

I'm in need to alternate two pumps using an Omron 10C3AR-A-V2 Zen program.

Here is the setup--

Float switch 2 - on - no operation

Float switch 3 - on - pump starts

Float switch 3 - off - continue pumping

Float switch 2 - off - stop pump

Which I have working great, but I cannot ,for the life of me, figure out how to get the other pump to run on the next cycle.

Any help is greatly appreciated.