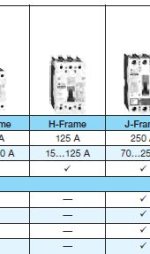

I thought 125 amp was the lowest I could buy becuase that what the AB config tool said below (the big link / very bottom of post).

In the manuals it looks like different sizes for the H frame. Also according to another document

http://www.ab.com/en/epub/catalogs/12768/229240/229254/305540/3087073/ the part number the configurator gave me is for a molded cases switch rated at 125 amp. this is located at the bottom of the page in the link above. Is the molded cases switch just that a switch but not really a breaker?

Also in the link above why are some of the 1 pole and 2 pole breakers fixed on the thermal trip and the magnetic trip so much higher that the current rating of the breaker? like a 15 amp 2 pole breaker has a fixed thermal trip and a magnetic trip of 500 amps?

I guess i need someone to help me understand how the therma; and magnetic trip are so different? I thought magnetic trip was like a dead short and thermal is gradual up to the rating like 15 amps on a 15 amp breaker?

Also why do they a have a breaking capicty at 50Hz and a Interrupt rating at 60 Hz

I am really having a tough time understanding this chart and would really be appreciative of some detailed help with it.

To not what OkiePC said what would be the best way for me to coordinate this so the panel breaker would trip before the MCC? The breaker in the MCC bucket will be 50 amps? do I need to buy a breaker with a lower amps? Will that handle coordination?

Rated

Current

In [A] Thermal Trip [A]

Ir =

In (Fixed) Magnetic Trip [A]

Im = 10 x

InBreaking Capacity (50 Hz)

Icu /

Ics [kA] Interrupting Rating (60 Hz)

[kA] Cat. No. 220…240V 380…415V 500V 690V 240V 480V 600/347V 15 Fixed 500 85 43 40 30 — — — — 85 35 22

140U-H3C2-C1520 Fixed 500 85 43 40 30 — — — — 85 35 22

140U-H3C2-C2025 Fixed 500 85 43 40 30 — — — — 85 35 22

140U-H3C2-C2530 Fixed 500 85 43 40 30 — — — — 85 35 22

140U-H3C2-C3035 Fixed 500 85 43 40 30 — — — — 85 35 22

140U-H3C2-C3540 Fixed 500 85 43 40 30 — — — — 85 35 22

140U-H3C2-C4045 Fixed 500 85 43 40 30 — — — — 85 35 22

140U-H3C2-C4550 Fixed 500 85 43 40 30 — — — — 85 35 22

140U-H3C2-C5060 Fixed 600 85 43 40 30 — — — — 85 35 22

140U-H3C2-C6070 Fixed 700 85 43 40 30 — — — — 85 35 22

140U-H3C2-C7080 Fixed 800 85 43 40 30 — — — — 85 35 22

140U-H3C2-C8090 Fixed 900 85 43 40 30 — — — — 85 35 22

140U-H3C2-C90100 Fixed 1000 85 43 40 30 — — — — 85 35 22

140U-H3C2-D10110 Fixed 1100 85 43 40 30 — — — — 85 35 22

140U-H3C2-D11125 Fixed 1250 85 43 40 30 — — — — 85 35 22

140U-H3C2-D12

Product Number: 140U-H6S3-D12

Link: http://raise.rockwellautomation.com/raconfig/validate.asp?pid=140U-H6S3-D12

Photo: http://raise.rockwellautomation.com/raconfig/rtcache/jpg/140uhfrm.jpg

Quantity: 1

Description: Molded Case Switch, H-Frame (up to 125A), 60...69 kA