Addohm

Member

Okay, so I have to admit something.. I never use OSR's, OSF's, or ONS's. Simply because the logic in using them eludes me. In my current small but extremely useful project, I am sure that a OSR could serve to fix my current dilema. Keep in mind this project is put together with spare parts. It wasn't done with the luxury of fast L/D and built in timer photo eyes. These are just basic retro-reflective photo eyes.

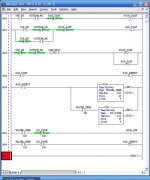

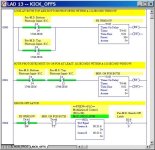

---PE1 [/]--------------------------TON1----

---PE2 [/]--------------------------TON2----

---TON1 [ ] ---TON2 [/]------------TON3----

----------------------------------|--------|

---------------------------TON3 [DN]--(OTL1)-

---OTL1 [ ]------------------------TON4----

----------------------------------|--------|

-----------------------------------TON5----

---TON4 [ ]---TON5 [/]-------------(OTE)---

---TON4 [DN]---TON5 [DN]---------(OTU1)---

I tried real hard If I have to screen shot it I will. At any rate, this is a part kick-off. If the bottom PE is made but the top PE isn't, it extends the cylinder.

If I have to screen shot it I will. At any rate, this is a part kick-off. If the bottom PE is made but the top PE isn't, it extends the cylinder.

The problem is the trailing edge of the part is not the same as the leading edge of the part, creating problems with my program.

Any suggestions?

---PE1 [/]--------------------------TON1----

---PE2 [/]--------------------------TON2----

---TON1 [ ] ---TON2 [/]------------TON3----

----------------------------------|--------|

---------------------------TON3 [DN]--(OTL1)-

---OTL1 [ ]------------------------TON4----

----------------------------------|--------|

-----------------------------------TON5----

---TON4 [ ]---TON5 [/]-------------(OTE)---

---TON4 [DN]---TON5 [DN]---------(OTU1)---

I tried real hard

The problem is the trailing edge of the part is not the same as the leading edge of the part, creating problems with my program.

Any suggestions?