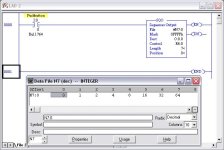

I am an Intern with on 2 classes in PLCs. I need help on using one input to control six outputs. I need to press the pb one time for the first light. Then press same pb again and next light come. The same pb input to cycle through all six outputs. I have idea how to do this. My first thought was to use a sequecner but cant get the data right. I dont know how to use the same input button to turn on all 6 lights. I want to learn to do it with a SQC and another way. I am a Novice. Please help. Can someone please post a rung example?

Last edited: