Excuse me if my questions sounds stupid but, I am totally new to PLC, and would like to learn about the type of PLC we use here.

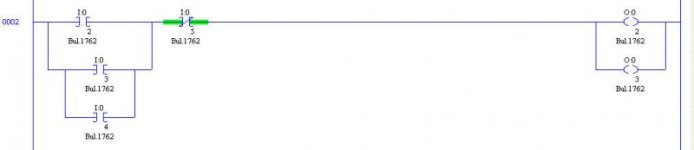

I have done a simple circuit using RS logix 500, one input and one output in series.

Input is an (examine if Open I:0/1) and the output is an (output energise).

Connecting it up practically, I have used a normally closed PB for the input and a lamp for the output.

As it is, I assumed that the lamp should be on but it isnt. Why? I have downoaded to the PLC.

I have done a simple circuit using RS logix 500, one input and one output in series.

Input is an (examine if Open I:0/1) and the output is an (output energise).

Connecting it up practically, I have used a normally closed PB for the input and a lamp for the output.

As it is, I assumed that the lamp should be on but it isnt. Why? I have downoaded to the PLC.