Maxtronick

Member

Hello.

I'm new at this forum and I have some trouble to solve.

I have here a HMI PV900 with RIO interface and I want to test this interface.

This HMI is out of it machine, so I cannot test with PLC that PV's program expects.

Then for this job I have here a allen bradley rack with a PLC 5/40 that contains RIO interface.

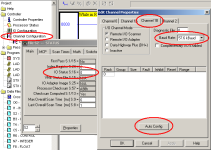

My problem is to configure a simple RIO network between this PLC 5/40 and PV900.

I'm new with PLC programming too, so I don't have knowledge enough for this job.

I tried to do it reading datasheet and forums.

But there's lot details to consider and I'm not getting it.

PS: My PV already has an application running and wouldn't want to change it for this test.

I hope someone help me.

I'm new at this forum and I have some trouble to solve.

I have here a HMI PV900 with RIO interface and I want to test this interface.

This HMI is out of it machine, so I cannot test with PLC that PV's program expects.

Then for this job I have here a allen bradley rack with a PLC 5/40 that contains RIO interface.

My problem is to configure a simple RIO network between this PLC 5/40 and PV900.

I'm new with PLC programming too, so I don't have knowledge enough for this job.

I tried to do it reading datasheet and forums.

But there's lot details to consider and I'm not getting it.

PS: My PV already has an application running and wouldn't want to change it for this test.

I hope someone help me.