Jon82387

Member

Hello everyone, i have searched this forum and looked here for advice before but this time i wasn't able to find an exact answer for what i'm trying to do.... I did find some good information but i just don't understand it enough to implement it.

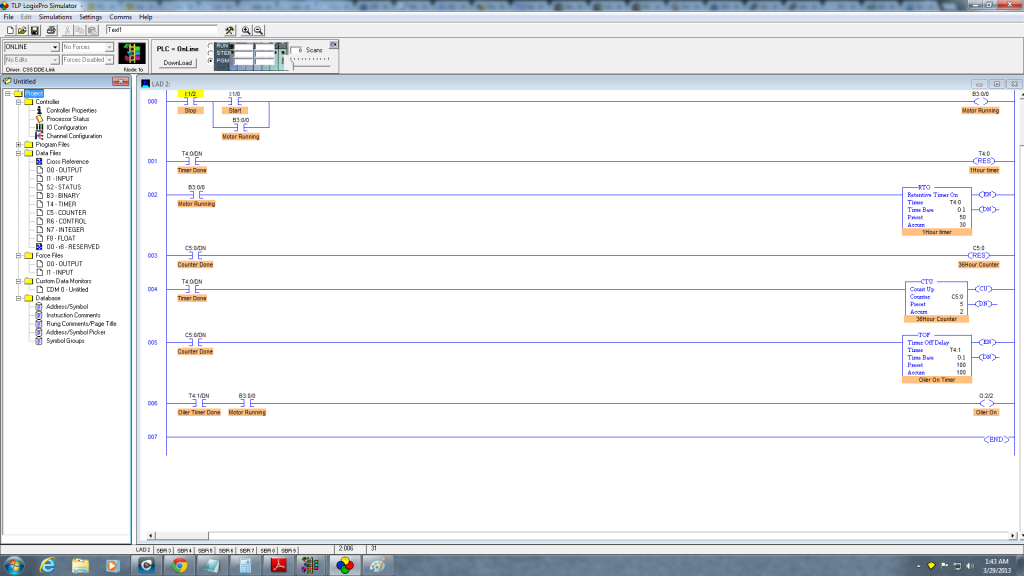

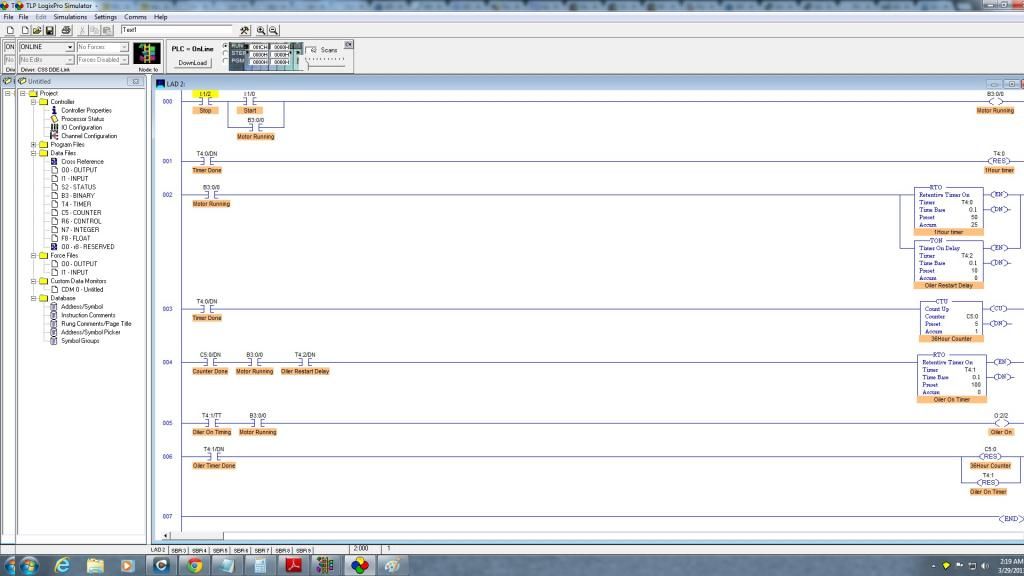

I am trying to add a 36hour timer instruction to an existing program we have at work. The timer would time for 36 hours when a certain motor/VFD is running, after the motor has ran for 36 hours it will start another timer that will energize a solenoid for an oiler to turn on for 1 minute and 5 seconds.

Now at first i thought this wouldn't be very hard.... but after finding out a standard timer would only go to around 9 hours..... i did more research as far as setting the timer to time for 1 hour then have a counter count up 36 times for the equivalent of 36 hours.

Then energize a Time Off Delay timer for the oiler for 1minute 5 seconds.

After adding in something to reset the 1 hour timer and everything my counter will count to 35 then it starts subtracting counts and i can't really figure it out.

After some research i found this thread http://www.plctalk.net/qanda/showthread.php?t=26446&highlight=36+hour+timer

Where TConnolly explains about using a timer setup that never times out.... now i can do the basics as far as programming goes but this explanation is a bit over my head i think. Can anyone elaborate a little on it?

I am trying to add a 36hour timer instruction to an existing program we have at work. The timer would time for 36 hours when a certain motor/VFD is running, after the motor has ran for 36 hours it will start another timer that will energize a solenoid for an oiler to turn on for 1 minute and 5 seconds.

Now at first i thought this wouldn't be very hard.... but after finding out a standard timer would only go to around 9 hours..... i did more research as far as setting the timer to time for 1 hour then have a counter count up 36 times for the equivalent of 36 hours.

Then energize a Time Off Delay timer for the oiler for 1minute 5 seconds.

After adding in something to reset the 1 hour timer and everything my counter will count to 35 then it starts subtracting counts and i can't really figure it out.

After some research i found this thread http://www.plctalk.net/qanda/showthread.php?t=26446&highlight=36+hour+timer

Where TConnolly explains about using a timer setup that never times out.... now i can do the basics as far as programming goes but this explanation is a bit over my head i think. Can anyone elaborate a little on it?