Your comments, please...

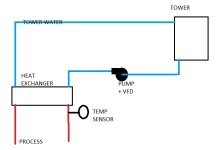

I'm trying to control the temperature of product through a plate heat exchanger using a water tower. What could be simpler?

Here's the setup: The water tower is about 100m distant from the heat exch. As far as I can tell, the lag is about a minute. The temperature sensor is on the product side of the heat exch.

Now the fun part. I wasn't allowed to use an analogue output on the remote i/o for the motor controls (sorry, can't afford it) so I've made the following in the (compactlogix) plc:

HMI-entered setpoint,

HMI-entered deadband; currently set at 0.5°C (divided by 2 and placed symetrically about the setpoint),

HMI-entered time between increment/decrement fan speed pulses; currently set at 40s. The pulse length is fixed at 2s and the inverter acc/dec is set to 30s.

So, when the product temperature is outside the deadband, the inverter is nudged up or down accordingly. For the most part it finds its way into the deadband and drifts very gently up or down before being corrected again. But if the disturbance is a bit too big then it doesn't settle down but just bounces off the limits.

Am I wasting my time on this one? Should I get the sensor moved to the water at the tower instead of via 100m of pipework?

I think I know the answer.

I'm trying to control the temperature of product through a plate heat exchanger using a water tower. What could be simpler?

Here's the setup: The water tower is about 100m distant from the heat exch. As far as I can tell, the lag is about a minute. The temperature sensor is on the product side of the heat exch.

Now the fun part. I wasn't allowed to use an analogue output on the remote i/o for the motor controls (sorry, can't afford it) so I've made the following in the (compactlogix) plc:

HMI-entered setpoint,

HMI-entered deadband; currently set at 0.5°C (divided by 2 and placed symetrically about the setpoint),

HMI-entered time between increment/decrement fan speed pulses; currently set at 40s. The pulse length is fixed at 2s and the inverter acc/dec is set to 30s.

So, when the product temperature is outside the deadband, the inverter is nudged up or down accordingly. For the most part it finds its way into the deadband and drifts very gently up or down before being corrected again. But if the disturbance is a bit too big then it doesn't settle down but just bounces off the limits.

Am I wasting my time on this one? Should I get the sensor moved to the water at the tower instead of via 100m of pipework?

I think I know the answer.