rbduck1

Member

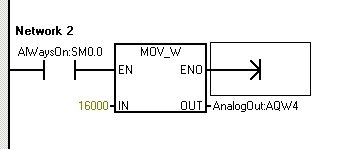

Good day guys (and gals) I have a question about what is required to get an analog output from a em232 analog output module connected to an s200 siemens cpu. I am fairly new to s200 progamming, but not new to troubleshooting.

I have a test cpu set up with a simple program loaded to test the analog output card. I have a signal enabling the card. I have it set for zero volts at 0 and 10 volts at 32000. I can't seem to get any voltage at the output. The analog output card is brand new. WHat could I possible be doing wrong?

I have a test cpu set up with a simple program loaded to test the analog output card. I have a signal enabling the card. I have it set for zero volts at 0 and 10 volts at 32000. I can't seem to get any voltage at the output. The analog output card is brand new. WHat could I possible be doing wrong?