Hi all..

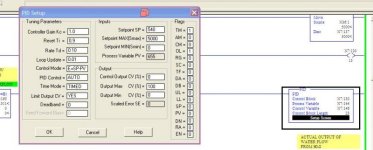

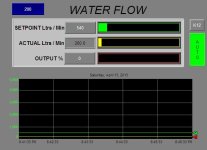

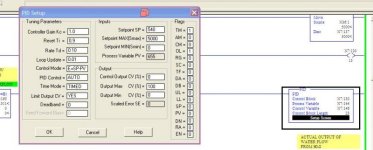

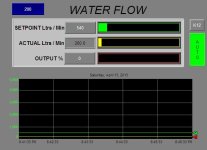

I've been reading through many of the posts on this Forum, lucky i found similar problem in-regard to PID Loop and concerning PID process control in RSLogix 500. I have developed a programmed the control incorporating all that I've gathered ideas on this site, however I am not getting the PID Loop to fully functional and control my intended process and wanted to ask a help from you and to all great mentors here in this forum, Did i something miss on my program?

Thanks a lot and for your patience..

I've been reading through many of the posts on this Forum, lucky i found similar problem in-regard to PID Loop and concerning PID process control in RSLogix 500. I have developed a programmed the control incorporating all that I've gathered ideas on this site, however I am not getting the PID Loop to fully functional and control my intended process and wanted to ask a help from you and to all great mentors here in this forum, Did i something miss on my program?

Thanks a lot and for your patience..

Attachments

Last edited: