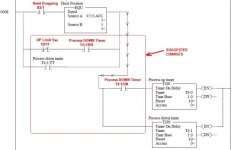

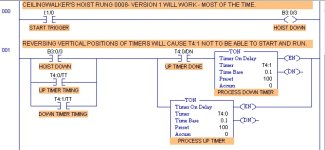

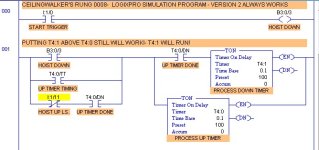

Oh. Okay. If you are timing the process, then you will not be able to use these process timers to help with the failing limit switches. You would need another set of timers for the hoist travel UP and DOWN times, to use as a check against the limit switches.

Sorry Lancie1, it was my inability to properly describe what exactly I was hoping to accomplish. I will try again;

1. Operator pushes fwd pb or rev pb for crane to move basket over plating tank. Crane uses input from prox switch mounted on its mounting rail to pass-by dogs. Each time it passes by a dog, it takes a counter value and adds one if fwd pb is pressed or subtracts one if rev pb is pressed. C5:0.acc is how the system knows which tank the crane is at. The actual name for that prox switch is "crane in position". Its main job is to let the control know it is ok (if energized) to drop the basket as it is in position over the tank.

2. Operator then pushes drop pb to drop basket into tank

3. Then there is a second prox switch located at the bottom of the crane and when the flight-bar crosses that switch it stops the drop process as it is now in the down position. I am now using all of these conditions (crane is at appropriate tank number and the flight-bar is down) to begin the process timer, which is timing-down.

4. The operator then takes the crane back to the loading station to pick-up the next basket, and the process is repeated (basket is moved over appropriate tank, flight-bar drops basket into the tank, timer begins timing) over-and-over....

5. When the down-timer expires, it will begin to time-up. Now, the main reason for the up-timer is for data collection. If too much alloy is removed it scraps the parts and there are times the operator's will swear up-and-down the basket wasn't in the tank but maybe an extra 5 minutes but we had no way to know if what they said was fact. So, when this up-timer begins there is a large serial device that displays the up-timers accumulator so that it can be viewed by the appropriate management team members. It also stores that value in the SCADA for later reference.

6. When the operator pushes the lift pb, as soon as PLC recognizes the crane is in a certain position and the operator pushes the lift pb, it will stop the timers and, again, that data is collected and stored and it also resets the timers for for the up and down-timers.

I have a couple of bugs with my project and I will bet you spot them immediately. When the conditions are right, and the hoist is passing-by the process tanks, sometimes it will reset the timers. I have some other goofy things that happen seemingly at random (timers will start without a basket actually being dropped into the tank for example)that I can not find a solution to. The problem is I have to quickly get in and get out as I can not stop production. I have a PLC at my desk that has a series of switches so that I am able to simulate this however, it works fine at my desk but after loading it into the processor and testing it, these other undesirable issues surface. I am attaching the latest version of my project. I really appreciate the help.