TheWaterboy

Lifetime Supporting Member + Moderator

This may be a dumb question for some but I gotta ask anyway.

Can someone give me the 50 cent tour of the reasoning behind all the different data formats and scaling needed when working with Analog modules in SLC and Micrologix?

I was used to PLC5 which was pretty simple and now mostly Contrologix which is really REALLY simple to implement. Scale an input from 0-100 and output to 4-20mA and they just work.

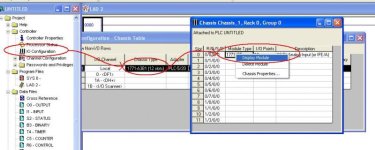

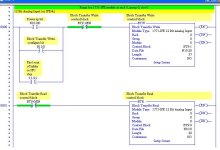

Lately I have been working with SLC 5/04, SLC 5/05 and some Micrologix 1200's and the analog Scaling required in these is truly bizarre when compared to the others I mentioned.

Using input scaling of 0 and 100 and a output scaling of 3687 and 16367 to get an output of 4-20mA is not intuitive in any way.

Will someone help me understand why this is necessary and if there is a way to understand the differences in a more intuitive way? Is it historical? or legacy?

Can someone give me the 50 cent tour of the reasoning behind all the different data formats and scaling needed when working with Analog modules in SLC and Micrologix?

I was used to PLC5 which was pretty simple and now mostly Contrologix which is really REALLY simple to implement. Scale an input from 0-100 and output to 4-20mA and they just work.

Lately I have been working with SLC 5/04, SLC 5/05 and some Micrologix 1200's and the analog Scaling required in these is truly bizarre when compared to the others I mentioned.

Using input scaling of 0 and 100 and a output scaling of 3687 and 16367 to get an output of 4-20mA is not intuitive in any way.

Will someone help me understand why this is necessary and if there is a way to understand the differences in a more intuitive way? Is it historical? or legacy?