Looking for some ideas here. I am trying to find a good way to verify that a rectangular part is orientated correctly.

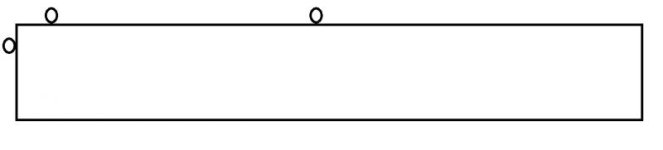

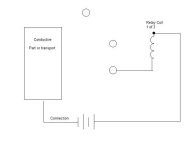

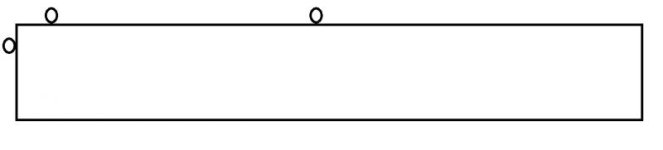

If you look at the picture below, that is the idea of the design. You have 3-4 stopper pins (Depending on length of part) that locate your part horizontally and vertically. What I would like to do is if a stopper pins comes in contact with the part, this will trigger an input within a plc. So each stopper pin has it's own input when in contact with the part. This way I know if I am not in contact with a certain stopper and sometimes I may need a sequence of hits so I can cycle between multiple combinations.

Now I think my best option is to do this with sensors but what kind of sensor would be good for this application?

If you look at the picture below, that is the idea of the design. You have 3-4 stopper pins (Depending on length of part) that locate your part horizontally and vertically. What I would like to do is if a stopper pins comes in contact with the part, this will trigger an input within a plc. So each stopper pin has it's own input when in contact with the part. This way I know if I am not in contact with a certain stopper and sometimes I may need a sequence of hits so I can cycle between multiple combinations.

Now I think my best option is to do this with sensors but what kind of sensor would be good for this application?