thinksabunch

Member

I’m working on programming multiple moves of a hydraulic cylinder in a block press. Block press can be seen in action here: [FONT="]www.youtube.com/watch?v=yIqTBQA8_Yo[/FONT]

[FONT="]

[/FONT]

To define positions of the moves in a closed loop, I have settled on a string potentiometer SP1-50-3 here: http://celesco.com/_datasheets/sp1.pdf I plan to be working with an AB PLC.

I understand that the string pot produces unique voltage levels as it is extended, which can be used to define any location along its length – in my case, those voltages define the positions of the cylinder at which I want the moves to happen.

So the pot voltages, through the PLC, will tell a hydraulic valve when to open, how much to open, when to close, and when to reverse.

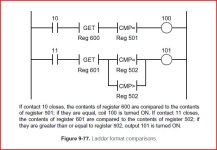

My knowledge void is in the instructions between the analog input of the PLC and the analog output.

I know the analog voltage from the string pot is converted into a digital code and stored in an analog input register somewhere. What I don’t know is exactly what to do from there. Obviously I have to enter the list of pot voltages (locations) at which I want the moves to happen and what I want to happen. (I believe what I want to happen has to be translated into other voltages translated into digital code, correct? So, do all the moves go into one instruction (register or what) or does it takes one instruction for each move? How are the instructions or the instruction sequence set up?

Can someone walk me though the sequence of setting one up?

I’m not sure how much time I’m asking for - so if it’s too excessive, let me know.

And thanks to those of you who have helped me so far – I appreciate it.

Barry

[FONT="]

[/FONT]

To define positions of the moves in a closed loop, I have settled on a string potentiometer SP1-50-3 here: http://celesco.com/_datasheets/sp1.pdf I plan to be working with an AB PLC.

I understand that the string pot produces unique voltage levels as it is extended, which can be used to define any location along its length – in my case, those voltages define the positions of the cylinder at which I want the moves to happen.

So the pot voltages, through the PLC, will tell a hydraulic valve when to open, how much to open, when to close, and when to reverse.

My knowledge void is in the instructions between the analog input of the PLC and the analog output.

I know the analog voltage from the string pot is converted into a digital code and stored in an analog input register somewhere. What I don’t know is exactly what to do from there. Obviously I have to enter the list of pot voltages (locations) at which I want the moves to happen and what I want to happen. (I believe what I want to happen has to be translated into other voltages translated into digital code, correct? So, do all the moves go into one instruction (register or what) or does it takes one instruction for each move? How are the instructions or the instruction sequence set up?

Can someone walk me though the sequence of setting one up?

I’m not sure how much time I’m asking for - so if it’s too excessive, let me know.

And thanks to those of you who have helped me so far – I appreciate it.

Barry