Nova5

Member

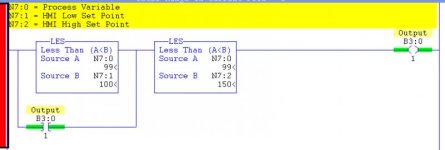

I need to turn a temperature element off at a high set point, let the tank drop to a lower set point before turning it back on. Although this is a insulated tank.

AB MicroLogix 1400.

Limit Test doesn't seem to do what I need, it would change the moment the temp shifted one degree back into the range. I'm looking for a 15 degree allowable fluctuation (or whatever the testing team sets through a HMI screen)

Greater Than / Less Than on the same rung also would seem to not work, as that would function the same as Limit Test.

N7 Integers will be used for the limit numbers.

Thoughts or suggestions on how to pull this off?

AB MicroLogix 1400.

Limit Test doesn't seem to do what I need, it would change the moment the temp shifted one degree back into the range. I'm looking for a 15 degree allowable fluctuation (or whatever the testing team sets through a HMI screen)

Greater Than / Less Than on the same rung also would seem to not work, as that would function the same as Limit Test.

N7 Integers will be used for the limit numbers.

Thoughts or suggestions on how to pull this off?