Matchu04

Lifetime Supporting Member

Hi guys a little help if possible.

1. I have made my self a little project, of trying to control a roller shutting door, just up and down if a PEC activated. I have programmed the up and down part but for the life of me struggling with the conditional part.

I want the door to open if it detects someone. I have done this by setting a mbit to set the output. When is reachs the high limit switch it resets the mbit. After 'x' the door comes back down.

Nice and easy... That bit works sweet.

The issue Im having is when try to put a condition in. Say the PEC is trigged while the door is either up or coming down. I want to restart the timer and start counting down again, or reopen the door and start again.

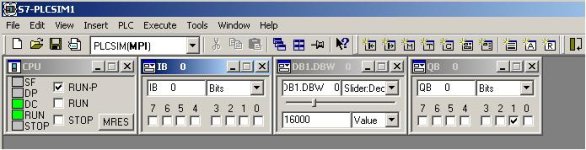

2. How to i post my code so you can have a look at what i have done so far.

I dont want the answer guys just guidence of how to get there. I have spent ages trying to get it to work correctly.

Please help....

1. I have made my self a little project, of trying to control a roller shutting door, just up and down if a PEC activated. I have programmed the up and down part but for the life of me struggling with the conditional part.

I want the door to open if it detects someone. I have done this by setting a mbit to set the output. When is reachs the high limit switch it resets the mbit. After 'x' the door comes back down.

Nice and easy... That bit works sweet.

The issue Im having is when try to put a condition in. Say the PEC is trigged while the door is either up or coming down. I want to restart the timer and start counting down again, or reopen the door and start again.

2. How to i post my code so you can have a look at what i have done so far.

I dont want the answer guys just guidence of how to get there. I have spent ages trying to get it to work correctly.

Please help....