Hello everyone,

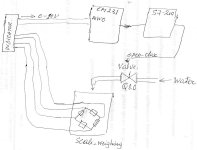

I want to weigh a certain amount of water (in kg). For this I use an S7-200 (CPU226) and EM231 analog module. I did the program in question, but I do not know if correct or not. Thank you for any help or advice. (I am a beginner in this field).

I want to weigh a certain amount of water (in kg). For this I use an S7-200 (CPU226) and EM231 analog module. I did the program in question, but I do not know if correct or not. Thank you for any help or advice. (I am a beginner in this field).

Last edited: