Hi guys ,

I know there is so many was to program plc, I'm after the best way to stop an output double triggering,

I was working on a machine last night which I could not get my head around, the application

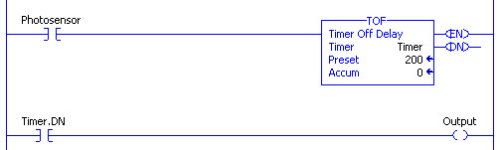

Is there is a product sensor which is triggering an output but if the product is not in line we get a double trigger I have put a timer in to try and control the trigger it worked better but still get a double trigger, the only way I can see is if I put a hold on circuit and a timer resets it any ideas that could help me , I'm not thinking straight guys thanks stu

I know there is so many was to program plc, I'm after the best way to stop an output double triggering,

I was working on a machine last night which I could not get my head around, the application

Is there is a product sensor which is triggering an output but if the product is not in line we get a double trigger I have put a timer in to try and control the trigger it worked better but still get a double trigger, the only way I can see is if I put a hold on circuit and a timer resets it any ideas that could help me , I'm not thinking straight guys thanks stu