Hello to all,

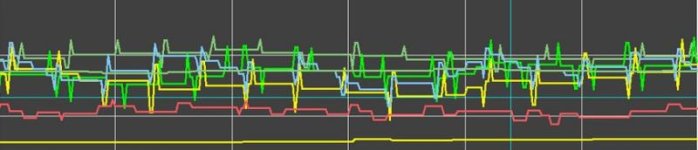

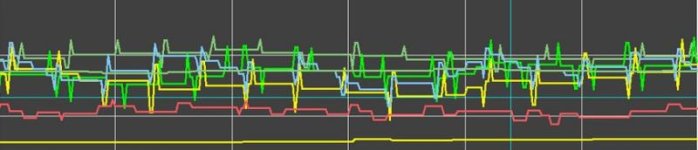

I have problem with thermocouple measurements in the plant. Almost all measurements in one signal cable experience sudden peaks like shown in pic1. I'm not sure how long this problem is present, but I assume very long. It was spotted only when we try to use some of the measurements in the control loops. Operators didn't notice this before, but in the last 6 months (that is how local archive is big) this is present. As you can see, there are sudden peaks in 3-5 °C in thermocouple measurements which disturb the control loops we implemented. This can be corrected with filtering but don't want to do that due to loop response and I'd like to find and eliminate the disturbance.

When I saw this it looked like to me as EM interference since almost all temperatures were affected.

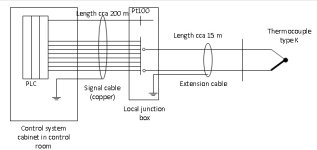

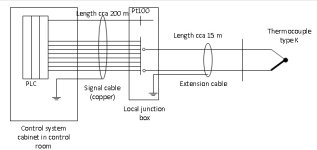

I'll explain how we measure the temperatures in our plant. The principle is shown in pic 2.

Thermocouple type K is used to measure the temperature (in this case steam) and from its head we use extension cable to the first local junction box in the field. In the same junction box arrive many extension cables from different thermocouples. From this junction box, copper signal cable is used to connect these measurements to the I/O modules of DCS. Pt100 is used to measure the temperature in the local JB so this can be compensated (cold junction compensation). This setup works very well through out the plant.

Extension cable has shield (drain) wire which is connected to the ground in the local junction box.

From the local JB we use larger copper cable type JE-Y(St)Y just like shown here: http://www.faberkabel.de/upload/datenblaetter/Datenblaetter/EN/DBL_JEYSTY.PDF

Shield (drain) wire is connected in the control cabinet to the ground and it is open on the other end (in the local junction box). So there should not be ground loop.

The connection to the ground is shown in pic 3. I have made the following tests:

1. I have disconnected the drain wire of copper signal cable in the cabinet (not standard solution) and connect it in the local junction box in the field, but that didn't help.

2. I have used different TC extension cable to the local junction box (without shield or drain wire connected to the ground in the JB)

3. I have connected drain wire of extension cable to the drain wire of big copper cable (this cable have as many as 10 measurements) without connecting to the ground in the JB and connect it only to the ground in the control room

4. I returned everything as originally designed (copper cable grounded in the control cabinet), while extension cable is grounded only in JB and used one free signal wire in the copper cable (I assumed drain is broken somewhere) and connect that free wire to the ground while disconnecting drain wire from the ground.

5. I connect drain wires on both ends to the ground (against the recommendation), just to check what is happening.

Nothing of these steps solved the problem (in some cases peaks were worse), so the only thing is to exchange the whole copper cable. I'm not sure how to explain this. Why this is happening only on this cable while we have very similar setups throughout the plant and it works OK? Before deciding to replace the big cable, I'd like to read your opinions on this.

Thank you!

Best regards,

Pandiani

I have problem with thermocouple measurements in the plant. Almost all measurements in one signal cable experience sudden peaks like shown in pic1. I'm not sure how long this problem is present, but I assume very long. It was spotted only when we try to use some of the measurements in the control loops. Operators didn't notice this before, but in the last 6 months (that is how local archive is big) this is present. As you can see, there are sudden peaks in 3-5 °C in thermocouple measurements which disturb the control loops we implemented. This can be corrected with filtering but don't want to do that due to loop response and I'd like to find and eliminate the disturbance.

When I saw this it looked like to me as EM interference since almost all temperatures were affected.

I'll explain how we measure the temperatures in our plant. The principle is shown in pic 2.

Thermocouple type K is used to measure the temperature (in this case steam) and from its head we use extension cable to the first local junction box in the field. In the same junction box arrive many extension cables from different thermocouples. From this junction box, copper signal cable is used to connect these measurements to the I/O modules of DCS. Pt100 is used to measure the temperature in the local JB so this can be compensated (cold junction compensation). This setup works very well through out the plant.

Extension cable has shield (drain) wire which is connected to the ground in the local junction box.

From the local JB we use larger copper cable type JE-Y(St)Y just like shown here: http://www.faberkabel.de/upload/datenblaetter/Datenblaetter/EN/DBL_JEYSTY.PDF

Shield (drain) wire is connected in the control cabinet to the ground and it is open on the other end (in the local junction box). So there should not be ground loop.

The connection to the ground is shown in pic 3. I have made the following tests:

1. I have disconnected the drain wire of copper signal cable in the cabinet (not standard solution) and connect it in the local junction box in the field, but that didn't help.

2. I have used different TC extension cable to the local junction box (without shield or drain wire connected to the ground in the JB)

3. I have connected drain wire of extension cable to the drain wire of big copper cable (this cable have as many as 10 measurements) without connecting to the ground in the JB and connect it only to the ground in the control room

4. I returned everything as originally designed (copper cable grounded in the control cabinet), while extension cable is grounded only in JB and used one free signal wire in the copper cable (I assumed drain is broken somewhere) and connect that free wire to the ground while disconnecting drain wire from the ground.

5. I connect drain wires on both ends to the ground (against the recommendation), just to check what is happening.

Nothing of these steps solved the problem (in some cases peaks were worse), so the only thing is to exchange the whole copper cable. I'm not sure how to explain this. Why this is happening only on this cable while we have very similar setups throughout the plant and it works OK? Before deciding to replace the big cable, I'd like to read your opinions on this.

Thank you!

Best regards,

Pandiani