cac1985

Member

Hello my name is cristian, I have little experience in programming. I want to make a variable speed motor with a powerflex 40 and mocrologix 1400, I read the manual

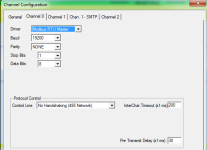

22b-um001_-in-e.pdf and a pdf with an example ModbusRTUControl_w_ML1500.pdf and that first I have to change the parameter P038 to 5, then write to the plc program a line of code where you add a block of MSG, but does not appear in the table options "modbus command" and "MD data address". Sorry if you do not understand, I'm from Argentina and my English is not very good. thanks

22b-um001_-in-e.pdf and a pdf with an example ModbusRTUControl_w_ML1500.pdf and that first I have to change the parameter P038 to 5, then write to the plc program a line of code where you add a block of MSG, but does not appear in the table options "modbus command" and "MD data address". Sorry if you do not understand, I'm from Argentina and my English is not very good. thanks