unsaint32

Member

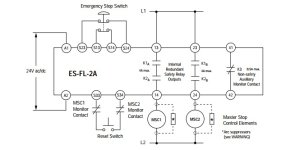

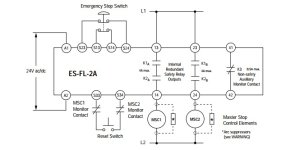

My understanding is that the S13 & S14 circuit has 24V+, and S23 & S24 circuit has 0V. And the K1 ... Kn coils energize only when the two circuits are closed. So, here are my questions.

Q1) I get 24V across S13 & S23 as I am supposed to, but why can't I get 24V across S13 terminal and the source GND?

Q2) Between S13 & S14, which is the source side?

Thanks.

Q1) I get 24V across S13 & S23 as I am supposed to, but why can't I get 24V across S13 terminal and the source GND?

Q2) Between S13 & S14, which is the source side?

Thanks.