You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Omron Zen PLC Counter

- Thread starter akosiak

- Start date

gtsuport

Member

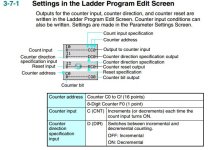

That is really my question I guess. Do I do this in the "edit contact" or "edit coil" field? I am trying to track occupancy so I need one input to increment the counter and another to decrement it.

I am working with the zen support software and selecting the "D" option in the edit contact field doesn't appear to change the count direction.

Thanks

I am working with the zen support software and selecting the "D" option in the edit contact field doesn't appear to change the count direction.

Thanks

Last edited:

gtsuport

Member

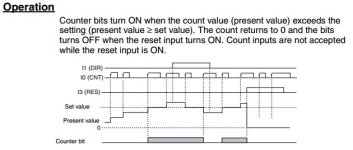

You will need to program both the CCx and DCx outputs.

To increment the count, energize the CCx output.

To decrement the count, you need to energize both.

Hope this will help.

To increment the count, energize the CCx output.

To decrement the count, you need to energize both.

Hope this will help.

gtsuport

Member

Yes, actually DCx needs to turn ON before or at the same time as CCx to decrement a counter. You can turn on DCx and leave it on until you are done counting down. When ready to count up, turn off or reset DCx, where x = counter number.Energize both simultaneously to decrement?

Padilla814

Member

Hey guys,

I am having a similar issue. I am using an Omron ZEN 10C3DR-D-V2 module with ZEN SOFT-01 Software Version 4.14

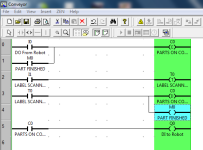

I am trying to have an input add a 1 to a counter and another input subtract 1 from the counter. If the counter reaches 3 an output will energize.

I have looked in the Edit screen for the Counter's Coil and Contacts and have been unable to see where I can have it actually subtract from the counter. Any help would be appreciated!

I am having a similar issue. I am using an Omron ZEN 10C3DR-D-V2 module with ZEN SOFT-01 Software Version 4.14

I am trying to have an input add a 1 to a counter and another input subtract 1 from the counter. If the counter reaches 3 an output will energize.

I have looked in the Edit screen for the Counter's Coil and Contacts and have been unable to see where I can have it actually subtract from the counter. Any help would be appreciated!

mendonsy

Member

I don't have a ZEN here at the moment, but it appears that toggling the direction input should do it. If you pulse the count input with the direction input OFF it should count up. If you pulse the count input with the direction input ON it should count down.

Padilla814

Member

Padilla814

Member

Are you student ?

I am in an electrical apprenticeship but this program is for work. Am engineer wanted me to come up with a way for our label scanning system to tie into our Fanuc robots.

Padilla814

Member

Why do you use M0 to subtract or decrement C0 at the end? It seems that your C0 count will end up to always be 0.

Perhaps you are not using C0 to actually count parts, but simply as a Step relay to indicate when the scanning of the label is complete. If so, there should be easier ways to do this.

Perhaps you are not using C0 to actually count parts, but simply as a Step relay to indicate when the scanning of the label is complete. If so, there should be easier ways to do this.

Similar Topics

Hi, after 30 years involved with automation I'm actually writing my first PLC program and am struggling a fair bit. My background is mechanical...

- Replies

- 8

- Views

- 1,874

I am new to PLCs and I bought an Omron Zen and I am trying to write some logic for a pneumatic crimper. Basically the pneumatics will get air to...

- Replies

- 9

- Views

- 3,068

I am new to the PCL - my history is "C" programming. I have a very simple PCL starter project. I am using the IO ports for input and the Q relay...

- Replies

- 7

- Views

- 3,405

I am very new so I will try to give as much information as possible. I cannot get a Prolific PL-2303TA USB to RS232 to connect to an Omron ZEN...

- Replies

- 1

- Views

- 1,587

Hi

I am setting a system up as per the attached picture, 5 inputs that are always present.

These are sensors I have in an injection mould, if...

- Replies

- 5

- Views

- 1,856