1) >It has 'TCP/IP modbus slave' module as a type of API.

Robo's Modbus slave documentation page

http://www.roborealm.com/help/Modbus_Slave.php

under [Program Extensions] says

"The Modbus Slave module provides an interface between RoboRealm and a modbus master . . ."

Do you have the Modbus slave module? It's required.

2) It appears that in the Robo that the variables are dynamically assigned Modbus registers according to the order your place them in the 'send variables' list. The register addresses appear to start with the register address in 'Address'.

So I would expect if the three variables Image count, FPS and POWER_DEVICE were in that order in 'Send variables' at address 50, that I'd see

00050 XXXXX (IMAGE COUNT)

00051 YYYYY (FPS)

00052 ZZZZZ (POWER_DEVICE)

in Modscan32.

Maybe, maybe not, that's why one experiments with Modscan to see what actually comes up, rather than blindly messing around with the PLC master.

3) Assuming you have the Modbus slave module, my suggestion is to setup the Robo to use an input register table starting at address 50 and then add a variable you want from the available variables list.

I don't know what 'automatic' means and they don't define it, so select 'integer' so that you know which format you'll be looking for.

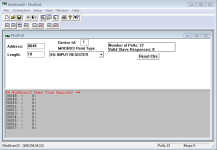

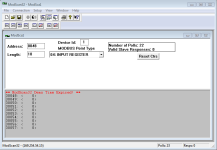

Then use Modscan32 (it runs for 5 minutes before it needs resetting unless its licensed) to attempt communication with the Robo.

Under connection > connect > Connection details, scroll up to select "remote modbus TCP server"

Enter the Robo's IP address.

Leave service port at 502.

click OK and see if you can get a connection.

On the work area, under Length: enter a value of 10, which will display 10 register on the work page.

Under Modbus Point type, select "04 input register"

For Address, enter 0048

In the toolbar, select the 3rd button from the left, the one with an I (when you put your cursor over it, it shows the word Integer). That will display data in integer format.

Modscan should read 10 registers starting at 00048.

presumably your variable will appear 00050.

I think you can save your settings so that when you re-open Modscan you can quickly set it up.

When Modscan successfully shows one variable that you can interpret, add another variable or two to check how the data 'looks' in integer format.

This will 'prove' the readabilty of the Robo via Modbus.

Then you can develop your PLC app knowing what it has to do to read the Robo.

What Fred is trying to tell you is that the Kepware OPC server will communicate with an OPC client that is running as an application or service on the PC. That's why Mr. Harbin is asking which PC software app you're dealing with, to see whether it's an OPC client.

An OPC server without an OPC client is somewhat useless.