roshane.nanayakkara

Member

Hi Guys

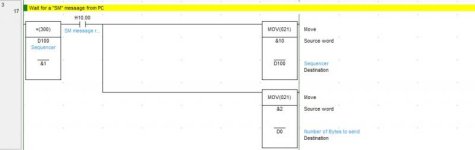

I'm a mechanical engineer who has been tasked with the job of modifying an existing PLC program. Now, while my knowledge is limited I have had a play around with the software and understand the basics of ladder logic. Where I am stuck is the PLC talks to a PC via RS232 using a predefined ASCII set of strings and with that came a few extra steps that got me a bit confused. If you guys can help me understand my existing program I'm sure I can modify it to meet my needs.

https://www.google.com.au/search?q=...w.ni.com%2Fwhite-paper%2F6534%2Fen%2F;368;364

Basically the PLC is used together with the PC to re-program some PCBA's (printed circuit boards) with new software. They are loaded in a test fixture (see link above) and the lid is closed which activates a lid sensor and part present sensors. Then a start button is pressed to start the programming. When programming is over the operator removes the PCB and loads a new PCB.

To start with, can someone please explain to me what D100,H10, &10 means? They are circled in the attached PDF (PLC Program v0.4)

What I think is D100 is the destination that stores the current step, &10 is step 10 maybe? I really don't know what H10 means.

Any help would be most appreciated.

Cheers

I'm a mechanical engineer who has been tasked with the job of modifying an existing PLC program. Now, while my knowledge is limited I have had a play around with the software and understand the basics of ladder logic. Where I am stuck is the PLC talks to a PC via RS232 using a predefined ASCII set of strings and with that came a few extra steps that got me a bit confused. If you guys can help me understand my existing program I'm sure I can modify it to meet my needs.

https://www.google.com.au/search?q=...w.ni.com%2Fwhite-paper%2F6534%2Fen%2F;368;364

Basically the PLC is used together with the PC to re-program some PCBA's (printed circuit boards) with new software. They are loaded in a test fixture (see link above) and the lid is closed which activates a lid sensor and part present sensors. Then a start button is pressed to start the programming. When programming is over the operator removes the PCB and loads a new PCB.

To start with, can someone please explain to me what D100,H10, &10 means? They are circled in the attached PDF (PLC Program v0.4)

What I think is D100 is the destination that stores the current step, &10 is step 10 maybe? I really don't know what H10 means.

Any help would be most appreciated.

Cheers