I have my earlier problem solved but this one is really getting to me. I have my direction issue solved , but I have another issue with my Actual Position High and Low.

SEW Movitools-MotionStudio

09. Bus Diagnostics

098 PI 2 1025 Actual Position High (Looks good)

099 PI 3 48229 Actual Position Low ( Looks good)

( Everything looks good here )

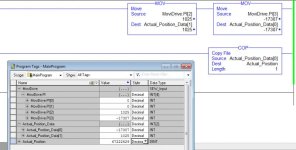

On the ControlLogix side..... This is my problem

Controller Tags

Movidrive.PI(2) 1025 Actual Position High ( Looks good)

Movidrive.PI(3) Actual Value wants to go +32767 to -32767. It seems like it should be the same as PI 3 in MotionStudio.

I thought I was onto something in MotionStudio looking at

27. Process Controller Input Values

28. Process Controller Limits

I got to have something messed up on the ControlLogix side.

Any thoughts on this ? I think I have one thing solved and then something else comes up.

Thanks,

SEW Movitools-MotionStudio

09. Bus Diagnostics

098 PI 2 1025 Actual Position High (Looks good)

099 PI 3 48229 Actual Position Low ( Looks good)

( Everything looks good here )

On the ControlLogix side..... This is my problem

Controller Tags

Movidrive.PI(2) 1025 Actual Position High ( Looks good)

Movidrive.PI(3) Actual Value wants to go +32767 to -32767. It seems like it should be the same as PI 3 in MotionStudio.

I thought I was onto something in MotionStudio looking at

27. Process Controller Input Values

28. Process Controller Limits

I got to have something messed up on the ControlLogix side.

Any thoughts on this ? I think I have one thing solved and then something else comes up.

Thanks,