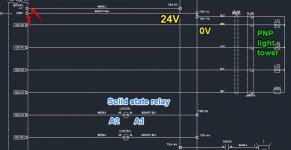

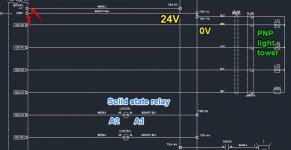

I am following an old electrical PLC design to make my machine. I think the diagram is not right. However, the machine has been built and working. I am not sure whether my understanding is wrong or some people fixed the machine after the drawing.

According to page 12 of http://literature.rockwellautomation.com/idc/groups/literature/documents/td/1769-td005_-en-p.pdf

The PLC has 16 sourcing digital output.

Note: I also find some information in Rockwell knowledge base question # 524618

My questions are

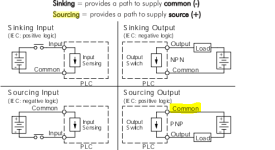

1. If it is sourcing output, should the light tower be NPN instead of PNP?

2. Would it be OK to switch the connection of the 2 RED arrows +V to GND and COM0 to 24V to make the output from Sourcing to Sinking?

3. Why the SSR work? It always has A1 connect to 0V. No matter what the PLC output, it has either no potential difference or negative potential difference

Please help

According to page 12 of http://literature.rockwellautomation.com/idc/groups/literature/documents/td/1769-td005_-en-p.pdf

The PLC has 16 sourcing digital output.

Note: I also find some information in Rockwell knowledge base question # 524618

My questions are

1. If it is sourcing output, should the light tower be NPN instead of PNP?

2. Would it be OK to switch the connection of the 2 RED arrows +V to GND and COM0 to 24V to make the output from Sourcing to Sinking?

3. Why the SSR work? It always has A1 connect to 0V. No matter what the PLC output, it has either no potential difference or negative potential difference

Please help