vachhaninimit

Member

Hello Guys,

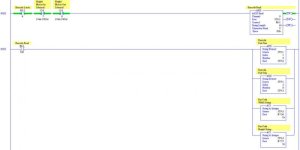

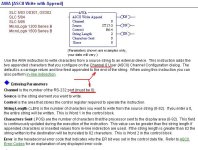

I am totally new to this forum and to PLC. I am trying to write a logic in PLC which reads ASCII line from Channel 2 and extract first 3 characters and again sends back to my program. I am attaching the pdf file which has my ladder logic.

The AEX instruction is causing the problem. I am not receiving the extracted characters back.

I am using rslogix 500 and micrologix 1400 series B with TCP/IP option.

I am totally new to this forum and to PLC. I am trying to write a logic in PLC which reads ASCII line from Channel 2 and extract first 3 characters and again sends back to my program. I am attaching the pdf file which has my ladder logic.

The AEX instruction is causing the problem. I am not receiving the extracted characters back.

I am using rslogix 500 and micrologix 1400 series B with TCP/IP option.

Last edited: