vampire791004

Member

Hi everyone, I am Francesco from Italy.

I need to make a system that controls if thermocouples are working good.

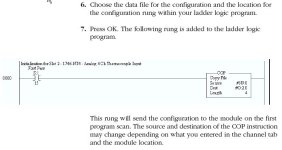

I was thinking to take micrologix 1400 and 1762-IT4 for it but i need to configure the channels from the program because the clinet can test any kind of thermocouples. It is possible to make this, i read the manual of the card and say that the configuration workd is readable and writeble but don't say where to find this world on the program.

Thanks to all.

I need to make a system that controls if thermocouples are working good.

I was thinking to take micrologix 1400 and 1762-IT4 for it but i need to configure the channels from the program because the clinet can test any kind of thermocouples. It is possible to make this, i read the manual of the card and say that the configuration workd is readable and writeble but don't say where to find this world on the program.

Thanks to all.