NetNathan

Lifetime Supporting Member

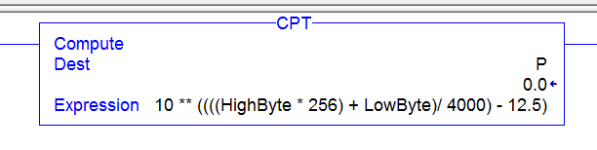

I have a pressure calculation to calculate in Controllogix.

The gauge is sending the high_byte and low_byte to Controllogix. I need to convert to the correct decimal format for vacuum level in millibar

Calculation required for conversion from gauge manual:

Pmbar = 10((high byte × 256 + low byte) / 4000 - 12.5)

Pmbar, high_byte, and low_byte are the tags and are INT

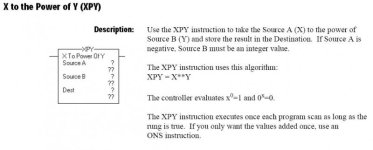

XPY block description:

The XPY instruction takes Source A (X) to the power of Source B (Y) and stores the result in the Destination.

In the XPY instruction, I am trying to use:

Source A=10

Source B = ((high_byte × 256 + low_byte) / 4000 - 12.5)

Dest = PmBar

On verify I am getting:

Error: Rung 2, XPY, Operand 2: Invalid expression or tag.

I a have tried removing outer parentheses using (high_byte × 256 + low_byte) / 4000 - 12.5 but same error

Do I need to calculate ((high_byte × 256 + low_byte) / 4000 - 12.5) in a different instruction and move that result to Source B?

..

The gauge is sending the high_byte and low_byte to Controllogix. I need to convert to the correct decimal format for vacuum level in millibar

Calculation required for conversion from gauge manual:

Pmbar = 10((high byte × 256 + low byte) / 4000 - 12.5)

Pmbar, high_byte, and low_byte are the tags and are INT

XPY block description:

The XPY instruction takes Source A (X) to the power of Source B (Y) and stores the result in the Destination.

In the XPY instruction, I am trying to use:

Source A=10

Source B = ((high_byte × 256 + low_byte) / 4000 - 12.5)

Dest = PmBar

On verify I am getting:

Error: Rung 2, XPY, Operand 2: Invalid expression or tag.

I a have tried removing outer parentheses using (high_byte × 256 + low_byte) / 4000 - 12.5 but same error

Do I need to calculate ((high_byte × 256 + low_byte) / 4000 - 12.5) in a different instruction and move that result to Source B?

..

Last edited: