Having some problems getting the logic straight for a traverse winder application.

Basically we have steel that has been previously slit being pulled by a nip roller and a rewinder with a hydraulic traverse winding it up.

Steel thickness (.010" to .060") and material Width (.25" to 1 7/8") is entered along with traverse width (0-16")

Both Motors are AC Black Max controlled by ABB ACS 880 VFD.

Nip roller operating in speed and rewinder in Torque mode.

I think once the nip roller starts to operate the rewinder will go also since it is trying to maintain torque. My problem is with the traverse winding. We want a nice even wind and smooth sides to the roll.

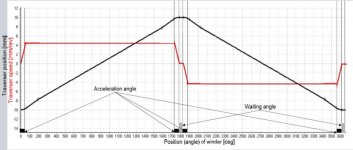

If I know the material width + Gap factor (Since I don't think it will be zero) it will give me pitch per rev. The problem is that the traverse is hydraulic not a motor.

Been doing a ton of reading and think I am confused more. (Maybe I need more input from operator, like angle or to calculate my roll width divide it by material thickness to have a calculated gap? Use dwell timers to hold the web before changing direction in the traverse? But then the rewind speed is going to change as the web builds up, so the time may change.....ahhhhhhhhh!!!

Basically we have steel that has been previously slit being pulled by a nip roller and a rewinder with a hydraulic traverse winding it up.

Steel thickness (.010" to .060") and material Width (.25" to 1 7/8") is entered along with traverse width (0-16")

Both Motors are AC Black Max controlled by ABB ACS 880 VFD.

Nip roller operating in speed and rewinder in Torque mode.

I think once the nip roller starts to operate the rewinder will go also since it is trying to maintain torque. My problem is with the traverse winding. We want a nice even wind and smooth sides to the roll.

If I know the material width + Gap factor (Since I don't think it will be zero) it will give me pitch per rev. The problem is that the traverse is hydraulic not a motor.

Been doing a ton of reading and think I am confused more. (Maybe I need more input from operator, like angle or to calculate my roll width divide it by material thickness to have a calculated gap? Use dwell timers to hold the web before changing direction in the traverse? But then the rewind speed is going to change as the web builds up, so the time may change.....ahhhhhhhhh!!!

Last edited: