This seems like it should be easy, but I can't seem to get it...

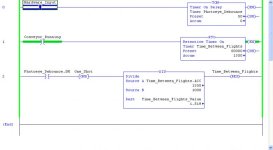

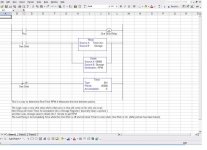

If I have a photocell that is blocked by material being dumped every time a conveyor flight comes by, how can I determine the length of time that elapses between the leading edge of the photocell being blocked and the leading edge of the next blockage of the photocell?

In other words... what is the frequency of the flights passing by a point?

thank you

If I have a photocell that is blocked by material being dumped every time a conveyor flight comes by, how can I determine the length of time that elapses between the leading edge of the photocell being blocked and the leading edge of the next blockage of the photocell?

In other words... what is the frequency of the flights passing by a point?

thank you