Hello all experts,

I'm a total beginner on PLCs and would need some guidance if possible. Basically I'm building a house (for my family) and I'm going to have a PLC system to control basically everything.

I'm only in the starting phase, have lighting from switches and similar to work. And now I'm trying to get something more fancy into the program.

From the beginning I was thinking of having power monitoring on a lot of places to determine power consumption in the house. But I have come to the conclusion that it would be rather expensive with HW and everything + using lots of space in the cabinet. So started thinking that PLC can basically calculate this for at least some of the consumers such as lighting.

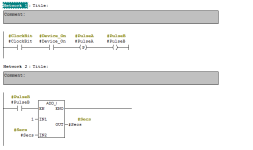

For example I know that a specific light is 45W, and if I monitor the time it is on I know how match it have used. So what I basically would like to do is to put a time stamp when each lamp is turned on in a data base. And when it is turned of put a off time stamp in the data base. Then calculate the amount of power it consumed. (The database of everything the PLC is doing is later on going to be written to log files in a PC in time intervals.)

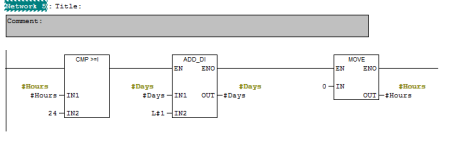

Then later on I would of course try to make this on-line so that it can be monitored live. I started with timers but if I understand it correctly the max time of a timer is 9990s = 2H 46M 30s. Maybe some counter to count the times the timer came to the end would be possible. But in the end there would need to be lots of timers and counters.

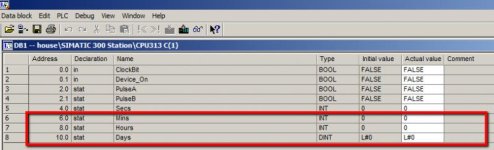

My current HW:

Siemens S7-300

CPU: 313C

Eth: CP343-1

and many DI/DO

Have anybody worked with similar time stamping and can guide me in the correct direction. Or knows a better/smarter way of doing above? Remember I'm not that advanced yet so basic explanation so that I understand

I'm a total beginner on PLCs and would need some guidance if possible. Basically I'm building a house (for my family) and I'm going to have a PLC system to control basically everything.

I'm only in the starting phase, have lighting from switches and similar to work. And now I'm trying to get something more fancy into the program.

From the beginning I was thinking of having power monitoring on a lot of places to determine power consumption in the house. But I have come to the conclusion that it would be rather expensive with HW and everything + using lots of space in the cabinet. So started thinking that PLC can basically calculate this for at least some of the consumers such as lighting.

For example I know that a specific light is 45W, and if I monitor the time it is on I know how match it have used. So what I basically would like to do is to put a time stamp when each lamp is turned on in a data base. And when it is turned of put a off time stamp in the data base. Then calculate the amount of power it consumed. (The database of everything the PLC is doing is later on going to be written to log files in a PC in time intervals.)

Then later on I would of course try to make this on-line so that it can be monitored live. I started with timers but if I understand it correctly the max time of a timer is 9990s = 2H 46M 30s. Maybe some counter to count the times the timer came to the end would be possible. But in the end there would need to be lots of timers and counters.

My current HW:

Siemens S7-300

CPU: 313C

Eth: CP343-1

and many DI/DO

Have anybody worked with similar time stamping and can guide me in the correct direction. Or knows a better/smarter way of doing above? Remember I'm not that advanced yet so basic explanation so that I understand