I believe Lancie is on the right track. The different drawings have different purposes and you run into problems trying to condense all that information. I am assuming you are using cordsets with your devices. I do this a lot for the equipment I currently work on.

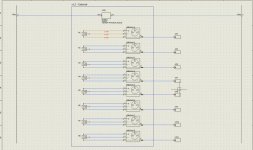

On the ladder diagram I show the from left to right a 24V connection, the proximity switch, and the signal terminated to the PLC. Additionally, I bring the 0V out of the bottom of the symbol and route that toward the bottom of the drawing to connect at 0V on the right. If there is an m12 or other QD that would cause a wire number/color change I indicate that here and provide a port number if there is one. I do not worry about showing the distribution box here because for the purposes of this drawing I don't think that is important and clutters the drawing.

I then have a connection drawing that is focused more on the physical layer. This is where I focus on showing the proximity switches connect to the cordsets and then to the distribution boxes. If the cordsets/cables are numbered I indicate that here. Because this drawing is focused more on the physical layer I use the 2d models supplied by the manufacturers for this drawing to show what they look like in the real world. I don't show the internal wiring of the distribution box because I have found it conveys little additional usable information, clutters the drawing some, and confuses the maintenance guys.

Finally I make a detail drawing of how to assemble the cables. I specify component/cable part numbers, assembly, terminations, and cable lengths here.

Long story short I break this out into three parts.

1. "Theory" - on the ladder diagram show how things are logically connected. Specify wire numbers and terminal numbers here.

2. "Connection" - show how the major components are connected on a connection diagram. Show the component, cordset, distribution block, and termination points. Label/number all of the aforementioned and specify a drawing for the cordset if necessary. Show the QD fittings here and precisely where on the distribution block they terminate.

3. "Physical" - show exactly how to assemble your cordset. Again, specify part numbers, cut lengths, and terminal numbers here for the cordset.

I have seen fewer errors during machine integration since I have broken the information down this way. It seems the crew I work with gets a little bit of information overload. This is my method and I would appreciate any feedback. Sorry about not having pictures handy.